1.Project description

CFD software is short for Computational fluid Dynamics software, which is specially used for the analysis, calculation and prediction of flow field. Through CFD software, the phenomena occurring in the flow field can be analyzed and displayed, the performance can be predicted in a relatively short time, and the best design effect can be achieved by changing various parameters. CFD numerical simulation can enable us to have a deeper understanding of the mechanism of the problem, provide guidance for the experiment, save the manpower, material resources and time required for the experiment, and play a good guiding role in the sorting out of the experimental results and the drawing of the law.

According to the air conditioning design scheme of a gymnasium, the fabric air distribution system is designed (the fabric air distribution system design can be referred to the drawing). According to the temperature and humidity requirements of the large space of the gymnasium and the design requirements of air flow organization, the air outlet mode of the fiber air distribution system adopts the jet air outlet mode. Through the jet air, jet nozzle to large space, long distance air supply. The jet nozzle is designed in rows on the air distributor. The jet nozzle accelerates the air flow, providing a very long range. The air flow organization simulation is carried out for the air conditioning design scheme of gymnasium, and the simulation results show that the design of the air outlet scheme meets the energy consumption requirements of the gymnasium for cooling and heating air supply.

2.Simulation scheme description

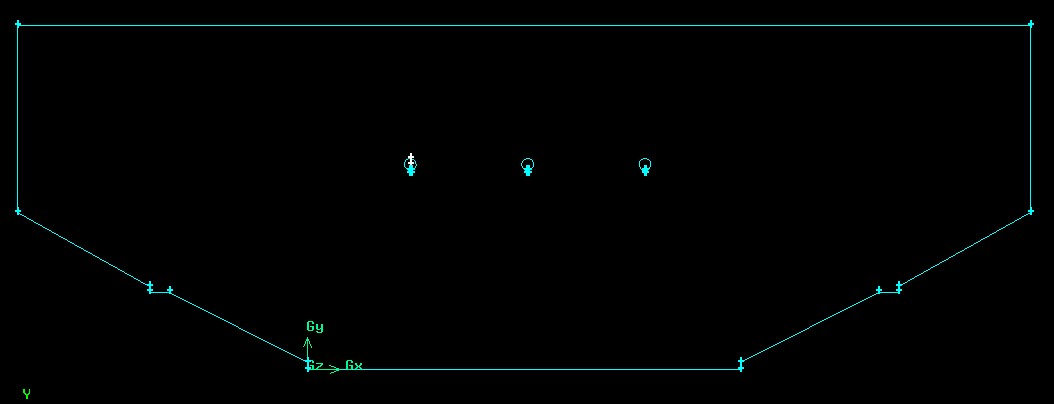

In practical applications, there are more jet jets arranged on the air distribution system, and the size of jet jets is smaller than that in the large space of the gymnasium. Therefore, when using the stadium 3D model for simulation, the simulation grid division time is long and cumbersome, and the simulation calculation time is relatively long according to the previous experience. Because this simulation scheme is only to study the effect of hot air, taking into account the above points, the gymnasium model is simplified in two dimensions. Figure 1 is a two-dimensional simplified model of the gymnasium. In Figure 1, the two-dimensional structure model is established according to the actual size of the gymnasium, and the geometric size and position size of the air distribution system are modeled strictly in accordance with the parameters in the drawing design.

Main parameter setting:

1. Choose K-E equation model, ideal incompressible gas.

2. The supply air temperature is 300K (27℃).

3. The return air entrance is located in the middle of the gymnasium.

4. Setting of boundary conditions: the wall surface is set to a constant heat flux boundary condition, and the corresponding heat load is set respectively. When setting the boundary conditions of the ground, the influence of personnel load is considered, and the extra heat flow brought by personnel activities is added on the basis of the heat flux of the maintenance structure. The roof increases the additional heat flow from the heat dissipation of the lighting equipment.

FIG. 1 Gymnasium structure model

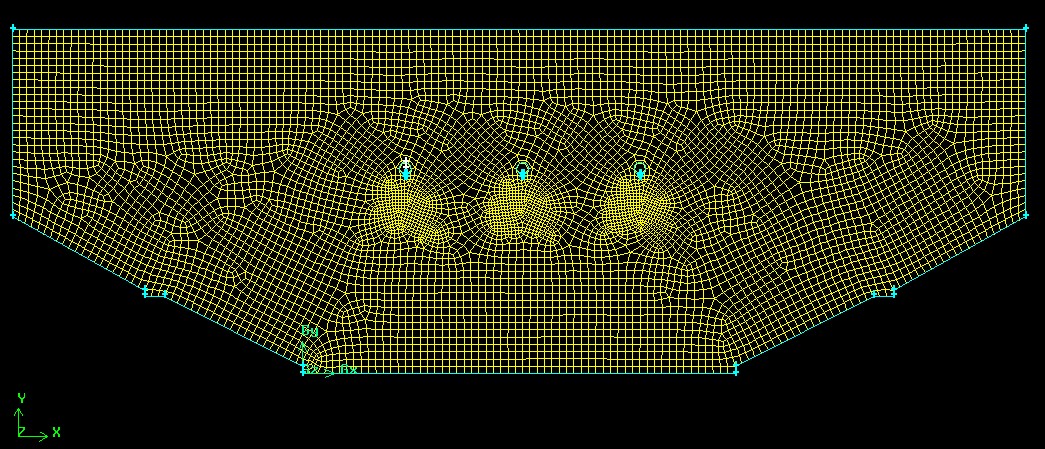

Figure 2 shows the meshing of the geometric structure. The mesh encryption for jet nozzle and return air is carried out to make the simulation results more accurate.

FIG. 2 Grid diagram of gymnasium structure model

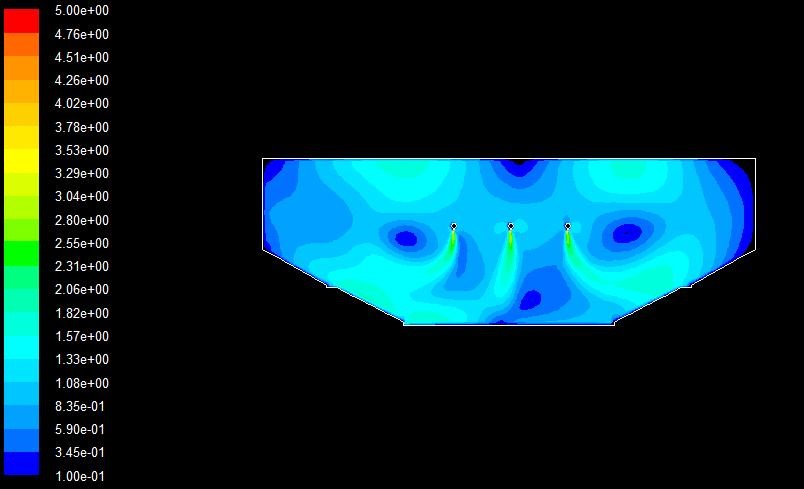

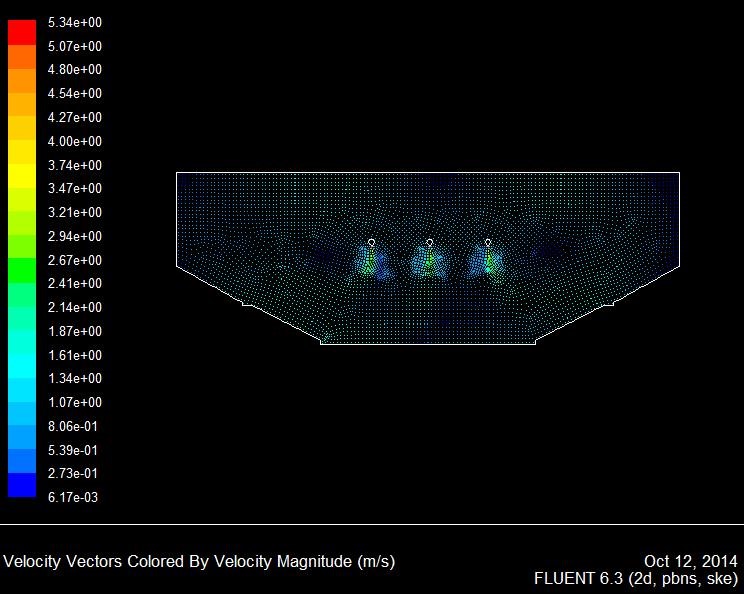

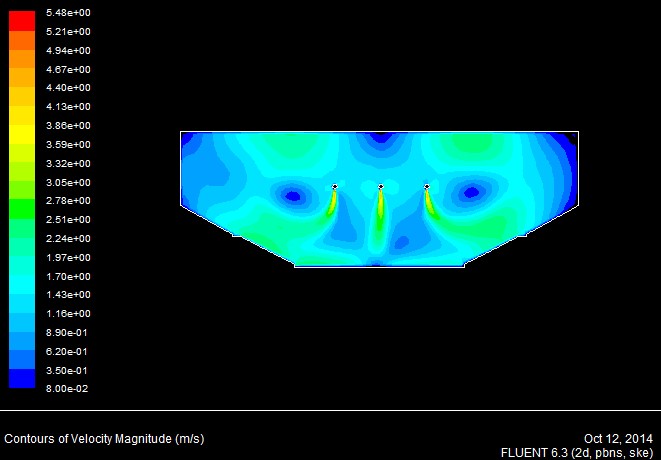

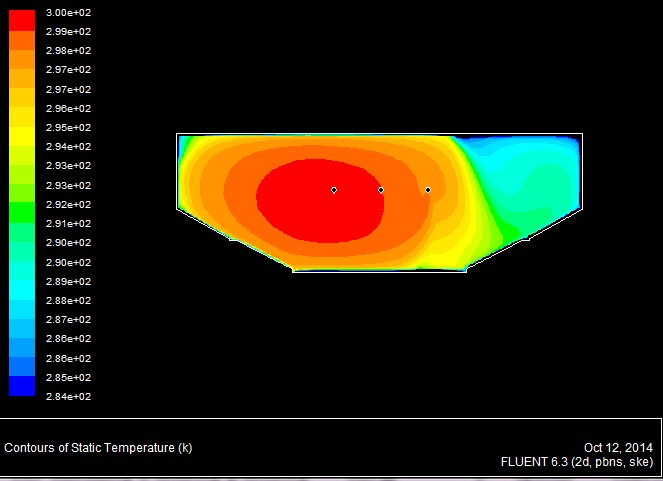

The air supply velocity of jet nozzle is optimized according to different project occasions and equipment parameters. The maximum air supply velocity of jet nozzle can reach 20m/s according to different design parameters of air distributor. In this simulation process, different air output velocity is adopted, and the inlet boundary condition is the fast inlet. The simulated inlet boundary conditions are: hot air at a temperature of 300K, considering the effect of gravity. Different heat loads were set on the four walls of the gymnasium. The simulation results show that the air distributor jet supply mode can meet the demand of hot air supply. FIG. 3 shows the simulation results of the velocity field of the gymnasium with the inlet velocity calculated at 5m/s. Figure 4 is the velocity vector diagram, from which the velocity direction and magnitude of each position in the flow field can be seen, and there is no zero value in the working area. FIG. 5 shows the simulation results of the velocity field with the inlet velocity calculated at 5.48m/s. Compared with FIG. 3, FIG. 4 and FIG. 5, when the inlet speed setting is lowered, the wind speed of the speed field in the working area of the gymnasium is reduced. Figure 6 is the temperature field calculated under the conditions of Figure 5, because the air distributor only considers the air conditioning area of the stadium area, it can be seen from the figure that the temperature field of the stadium area meets the design requirements. If the air supply organization of the audience area is reasonably designed in the simulation process, the uniform temperature distribution can be achieved in the field area.

The results of the above simulated junctions are obtained under certain initial indoor and outdoor temperatures, and the corresponding simplification, and the simulation process considers the space closed and other conditions. The actual air supply process may vary. However, the overall speed and temperature variation trend are relatively accurate, and the simulation results can be used to assist the design of fiber air duct and provide some guidance for its effect verification.

According to the regulations of the air supply speed of the gymnasium in the HVAC code, the suitable jet nozzle is selected to fully meet the demand of hot air supply.

FIG. 3 Inlet 5m/s velocity field

Figure 5 Velocity field of 5.48m/s at the entrance

FIG. 6 Temperature field simulation diagram with inlet wind speed of 5.48m/s