A、Customer demand survey。

|

Customer demand survey form |

|||

|

Project name: |

Date: |

||

|

preparer: |

Tel: |

||

|

Project Information |

Ventilation condition:Cooling () Heating () Fresh air () Dual heating and cooling () |

||

|

Top structure:Ceiling type () Open type () |

|||

|

Room use:Industrial plant () Sports Venue () Shopping Mall Supermarket () Office () Restaurant () Other () |

|||

|

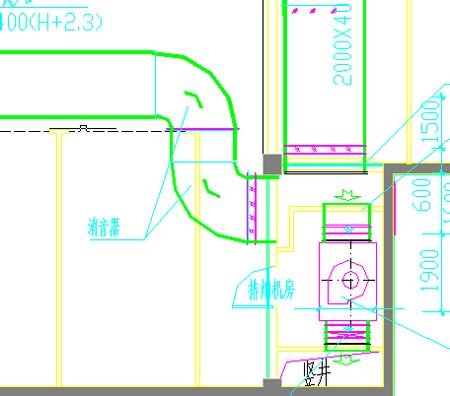

Air treatment end program:() Station location has been determined () |

|||

|

Air handling end parameters: air volume () Air pressure () Cooling capacity () heating capacity () |

|||

|

Maximum allowable wind speed in the air supply area

|

Height between the air supply position and the ground

|

||

|

Air supply area (length × width):( )meter×( )meter |

|||

|

Other requirements (please specify): |

|||

| remark: |

Please provide us with the architectural design plan, elevation and section

diagram of the project (including the installation position of the air treatment end).

|

||

B、project design。

Make the preliminary design of the project according to the customer demand questionnaire,

project drawings, and telephone communication with the customer details.

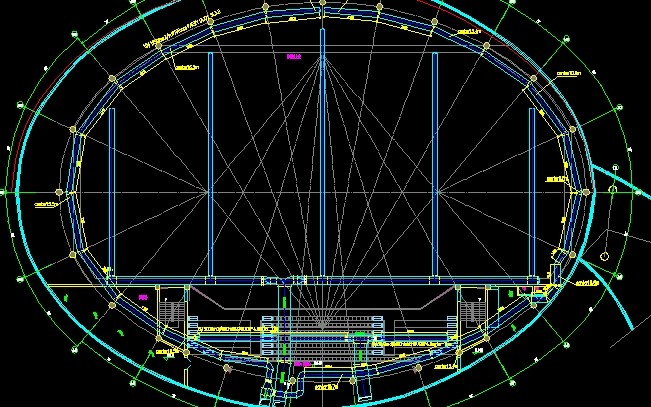

(1)、planning layout

According to the characteristics and requirements of the project, a reasonable MX fabric air

distribution system is arranged to ensure that the air distribution can meet the customer's

air supply range.

(2)Design pipe diameter

The optimum pipe diameter is designed according to the end parameters of air treatment, pipe

layout, shape selection and the requirements of air velocity in MX fabric air distribution

system.

。

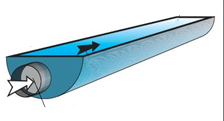

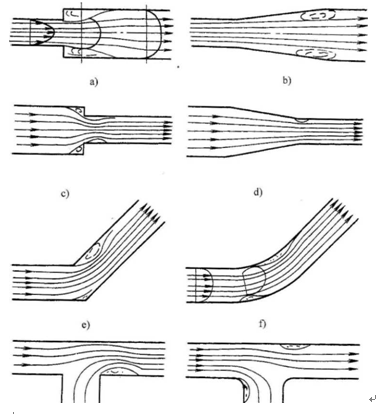

(3)Drag calculation

The wind resistance includes the resistance along the path and the local resistance. After

calculating the total resistance of the designed system, the dynamic pressure and static

pressure in the air distribution system of MX fabric can be calculated。

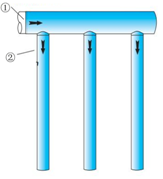

(4)Aperture design

MX fabric air distribution system belongs to the principle of static pressure air supply, according to the

calculated static pressure and the required air supply distance, design the best size and number of

holes (including the air supply design of mesh strips, holes and spout)。

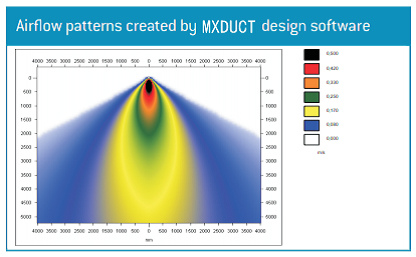

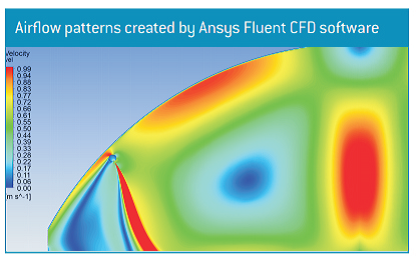

C、Airflow structure simulation

According to the application requirements, the air flow organization simulation is carried out for the

completed scheme, and the shortcomings of the scheme are optimized。

D、Finalize the final plan

The optimized scheme is provided to the customer. If the customer has new requirements for the scheme,

the design can be changed. If the customer is satisfied, it will become the final scheme.